Glass bottle packaging is mainly used in food, beverage, cosmetics, medicine and other fields. Among them, the liquor packaging market is the main position of glass bottles. Domestic glass bottle manufacturers have concentrated production bases from Linzhou in Henan Province to Yuncheng in Shandong Province, Xuzhou in Jiangsu Province and Longchang in Sichuan Province. Each region has its own industrial belt, which has also spawned a number of glass bottle supporting enterprises. We can see that from wine bottles to white wine bottles to beer bottles, we can see that glass bottles occupy an absolutely dominant position in the wine bottle market. In the cosmetics and medicine bottle market, glass bottles, with their advantages of heat resistance, pressure resistance and cleaning resistance, can not only be sterilized at high temperature, but also stored at low temperature. They also occupy a position that cannot be replaced by other wine bottle packaging manufacturers.

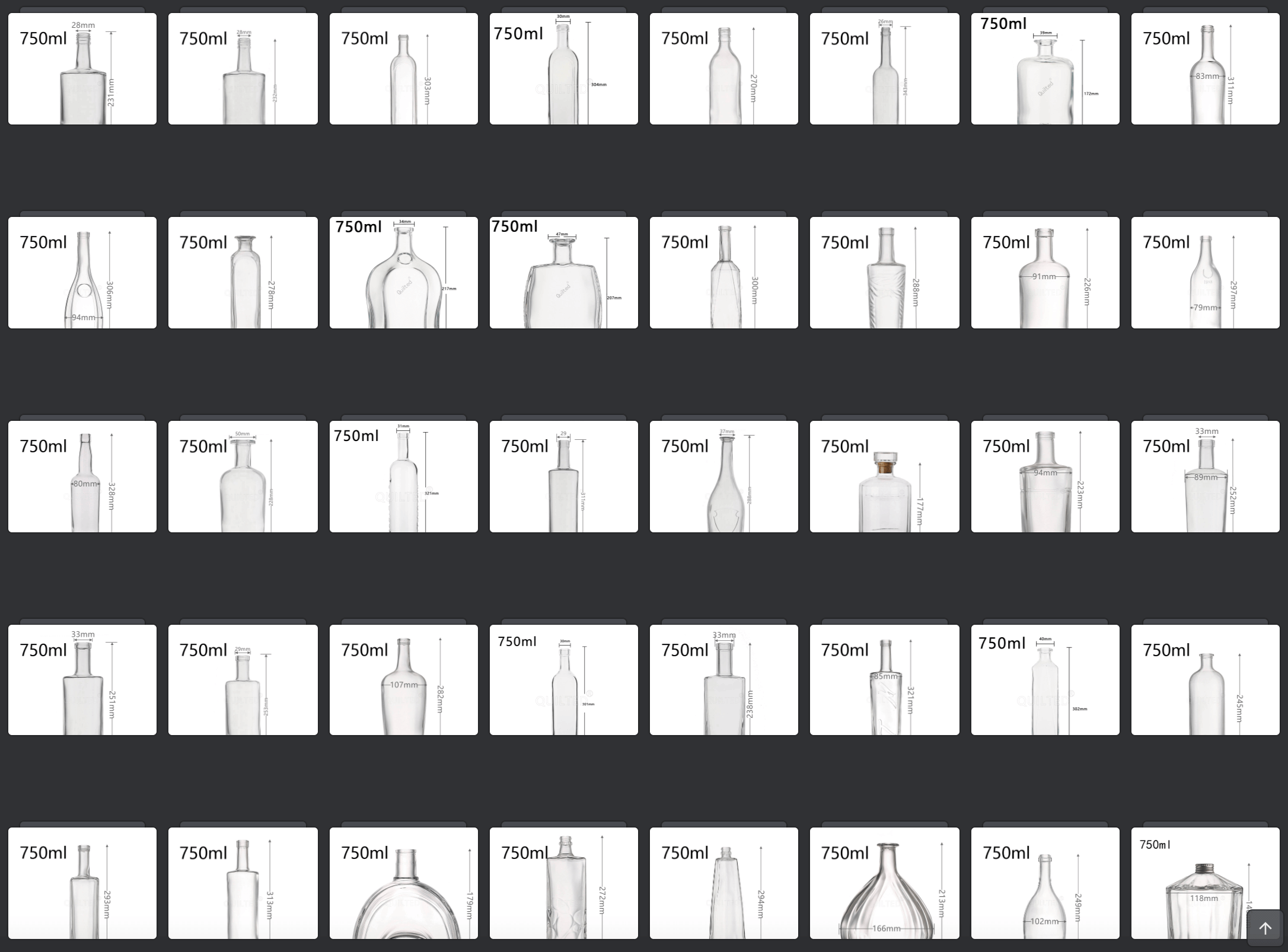

1. The difference of bottle shape design of glass liquor bottle; Lack of characteristics and characteristics is a common problem of most products in the market. In the process of market circulation, there is an obvious lack of product characteristics and differentiation, resulting in consumers’ lack of awareness of products and brands. How to quickly attract consumers’ attention to your products on the shelf is one of the factors that products must have.

2. Brand temperament of glass spirit bottle type; The temperament conveyed by bottle design should be consistent with the brand. Brand awareness is accumulated in the long-term marketing process. Each product needs to be the same as the overall temperament concept of the brand, so that consumers can establish an overall mental impression of the brand. There are many ways for wine bottles to add their own characteristics. The common ways are spraying, silk screen printing, decals, carving, frosting, electroplating, etc

Coloring process

1. Electrochemical aluminum: the outer surface of aluminum is wrapped with a layer of film on the inner plastic.

2. Electroplating (UV): compared with spraying, the effect is bright.

3. Spraying: the color is dull compared with electroplating.

Internal bottle external spraying: spraying is carried out on the outside of the internal bottle. There is an obvious gap between the internal bottle and the external bottle when viewed from the outside. The spraying area is small when viewed from the side.

Spray inside the outer bottle: spray paint on the inner side of the outer bottle, which looks large in appearance, small in vertical plane, and has no gap with the inner bottle.

4. Wire drawing covered with gold and silver: it is actually a film. Careful observation can find the gap on the bottle.

5. Secondary oxidation: secondary oxidation is carried out on the original oxide layer, so that the smooth surface is covered with a pattern of dark and dumb surface or the dark and dumb surface appears a pattern of smooth surface. It is mostly used for the production of logo.

6. Injection color: it is a relatively cheap process to add toner to the raw materials during injection molding. Bead powder can also be added. Adding too white powder will turn the transparent color of pet into an opaque color.

Printing process

1. screen printing: one is high-temperature ink screen printing, which is characterized by not easy decolorization, dull color, and difficult purple color matching effect; the other is low-temperature ink screen printing, which is colorful and has high requirements for ink, otherwise it is easy to fall off, and attention should be paid to bottle disinfection.

2. hot stamping: a thin layer of paper is used for hot stamping, so there is no concave convex feeling of silk screen printing.

3. water transfer printing: it is an irregular printing process carried out in water. The printed lines are inconsistent and the price is more expensive.

4. heat transfer printing: heat transfer printing is mainly used for products with large quantity and complex printing. It belongs to attaching a layer of film on the surface, and the price is too expensive.

5. offset printing: it is mostly used for aluminum-plastic hoses and all plastic hoses. If the offset printing is made of colored hoses, it must use silk screen. The background color will show through the offset printing, and sometimes a layer of bright film or dumb film will be attached to the hose surface.

3. The bottle shape design of glass wine bottle shall conform to ergonomics; Whether it can conform to people’s daily habits when placing and pouring wine, and easily pick it up and put it down. We should not blindly pursue the unique shape without considering whether it is convenient in use.If you need free samples, please contact us

Post time: 6月-23-2022