The quality of imported glass bottles has always been one of the important issues that customers are concerned about. As a company specialized in glass bottle production and export, we have been committed to providing customers with high-quality and reliable products and services.

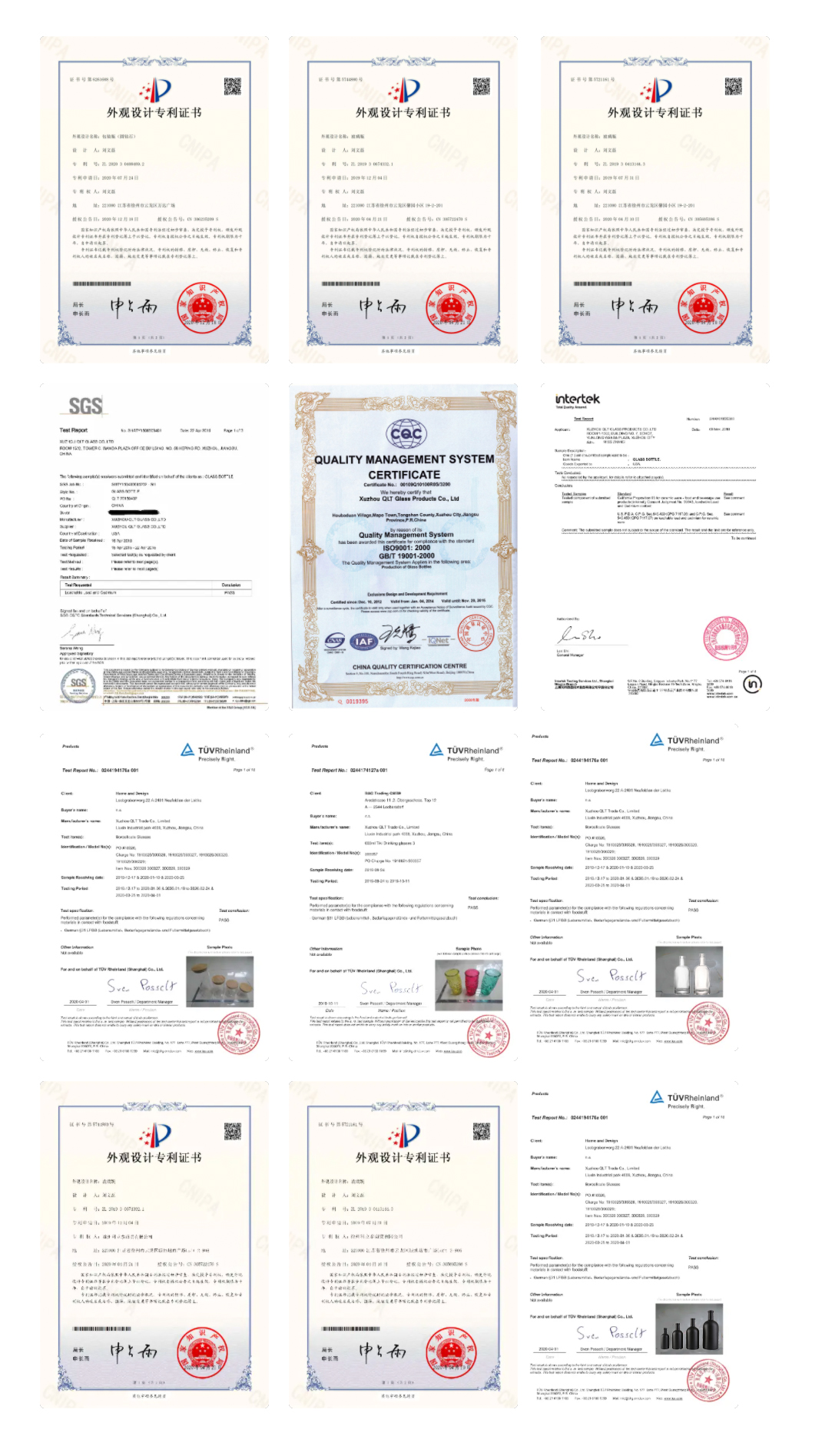

Firstly, our glass bottles are regularly sampled and sent to various third-party authoritative testing organizations such as LFGB, TUV, and SGS for testing, with a 100% pass rate for sampling. If you need relevant certificates, please click here to obtain them.

Secondly, we have a wide range of product types, including over 1700+ wine bottle samples, covering various capacities, shapes, and colors to meet the needs and requirements of different customers. If you need a product catalog, please click here to contact us.

Thirdly, we attach great importance to product delivery and provide timely and accurate delivery services to customers. We cooperate with multiple international logistics companies to provide customers with flexible logistics solutions, ensuring that products are delivered to customers on time and in the required quantity. Our logistics services cover multiple countries and regions worldwide and can meet various export needs of customers.

Finally, we have strong export capabilities and rich export experience, and can provide customers with professional export services. We are familiar with international trade rules and relevant laws and regulations, and can provide customers with comprehensive export consultations and support. Our export business covers multiple countries and regions, including Europe, North America, South America, Asia, etc., and has rich export experience and resource advantages.

In our company, customer satisfaction is our top priority. We are committed to providing customers with high-quality and reliable products and services to ensure that customers are satisfied and trust our brand. If you have any questions or needs regarding our products and services, please feel free to contact our customer service team, and we will be happy to assist you.

Below are some of the relevant laws and regulations on glass bottles in China and some other countries, which will undoubtedly bring a bright future for glass bottles.

In China, various relevant departments have a series of clear and strict regulations and management methods for the packaging, production, and use of glass bottles. Here are some of the main ones:

- “Food Safety Law”: This law stipulates that glass bottles used for drinking water, alcohol, food, and other purposes should meet relevant safety standards.

- “Glass Bottle Industry Standard”: This standard stipulates the basic requirements, classification, size, physical inspection, marking, packaging, storage, and other aspects of glass bottles.

- “Glass Bottle Production License Management Measures”: This measure stipulates that glass bottle production enterprises must hold a production license and formulate management systems for license application, approval, change, cancellation, etc.

- “Glass Bottle Inspection Regulations”: This regulation stipulates the various inspection items for glass bottles, including appearance, size, physical properties, chemical properties, optical properties, and other requirements.

- “Management Measures for Recycling and Utilization of Glass Bottles”: This measure stipulates the management system for the recycling and utilization of glass bottles, including the qualification requirements of recycling institutions, safety and sanitation management during the recycling process, classification, storage, and transportation of recycled glass bottles, and other requirements.

Translation: According to the “Industry Standard for Glass Bottles” (GB/T 19673-2019), the following contents regarding the basic requirements, classification, dimensions, physical inspection, labeling, packaging, storage, and other aspects of glass bottles are specified:

- Basic requirements: Glass bottles should meet national safety standards, have no significant defects, and their surfaces should be smooth, clean, and free of scratches, bubbles, and cracks.

- Classification: Glass bottles are classified into three categories based on their purpose, shape, and other factors, including mouth type, capacity type, and special-purpose type.

- Dimensions: The corresponding size standards for different types of glass bottles are specified, including mouth diameter, height, bottom diameter, and volume.

- Physical inspection: This includes aspects such as appearance inspection, dimension inspection, physical performance inspection, chemical performance inspection, optical performance inspection, etc.

- Labeling: The content and location of the labeling for glass bottles are specified, including the manufacturer’s name, model specifications, volume, net weight, and quality.

- Packaging: The packaging requirements for glass bottles are specified, including packaging materials, packaging methods, and packaging labeling.

- Storage: The storage requirements for glass bottles are specified, including storage locations, storage methods, and storage periods.

In addition, according to the “Glass Bottle Inspection Regulations” (GB/T 19431-2019), the requirements and details for various inspection items for glass bottles, including appearance, dimensions, physical performance, chemical performance, optical performance, etc., are specified as follows:

- Appearance inspection: This includes inspecting whether the bottle body is flat, whether there are defects such as bubbles, cracks, scratches, etc., and whether the dimensions and shapes of the bottle mouth, bottom, and other parts meet the standards.

- Dimension inspection: This includes inspecting whether the dimensions, such as the mouth diameter, height, bottom diameter, and volume, meet the standards, and whether the geometric shapes, such as the roundness of the mouth and straightness of the bottle body, meet the standards.

- Physical performance inspection: This includes inspecting the bottle body strength, heat resistance, cold resistance, temperature change resistance, heat shock resistance, and other aspects.

- Chemical performance inspection: This includes inspecting the chemical stability, corrosion resistance, solubility, and other aspects of the glass bottle.

- Optical performance inspection: This includes inspecting the light transmission and chromaticity of the glass bottle.

Furthermore, these regulations also specify the inspection methods and standards, the judgment criteria for inspection results, and the requirements for inspection records and reports. These inspection items and regulations aim to ensure the quality and safety of glass bottles and provide reliable technical support for the production and use of glass bottles.

Translation: The inspection and testing standards for glass bottles may vary in different countries and regions. Here are some relevant standards and specific details for some countries or regions:

- European Union (EU): The EU mainly refers to international standards such as ISO 719 and ISO 718 for the inspection and testing of glass bottles. In addition, the EU has also developed some standards for specific types of glass bottles, such as the Pharmaceutical Glass Standards (EP), Wine Bottle Standards (DIN 228), Food Glass Bottle Standards (DIN 6120), etc.

- United States: The US Food and Drug Administration (FDA) has issued a series of standards for glass bottles, including requirements for production, packaging, labeling, storage, and transportation. In addition, some private organizations in the US have developed testing standards for glass bottles, such as the Glass Packaging Institute (GPI) and the National Glass Association (NGCA).

- Japan: Japan has developed standards for pharmaceutical glass bottles, including JIS R3501 and JIS R3502. In addition, Japan has also established some standards and regulations for the packaging, labeling, storage, and transportation of glass bottles.

- Australia: The Australian Standards Bureau has developed the AS/NZS 2233 series of standards, including AS/NZS 2233.1, AS/NZS 2233.2, etc., which specify the requirements for glass bottle dimensions, thickness, volume, physical performance, chemical performance, etc.

Among them, the Wine Bottle Standard (DIN 228) is one of the European standards for wine bottles, which is applicable to the production and use of various wine bottles. The standard specifies the specific details of the bottle shape, size, capacity, material, and quality requirements, including:

- Shape: Wine bottles should be cylindrical, with a straight barrel-shaped mouth and a flat or hemispherical bottom.

- Size: The size of wine bottles should comply with the standard, including the mouth diameter, height, bottom diameter, etc.

- Capacity: The capacity of wine bottles should comply with the standard, usually 0.25 liters, 0.5 liters, 0.75 liters, 1 liter, 1.5 liters, 2 liters, etc.

- Material: Wine bottles should be made of glass material, which can be transparent, amber, green, etc., but should comply with relevant national standards.

- Quality requirements: Wine bottles should be free of significant defects, with a smooth and clean surface, and without defects such as bubbles, cracks, and scratches. In addition, the weight of wine bottles should comply with the standard, and the glass thickness should comply with relevant national standards to ensure the bottle’s strength.

The Wine Bottle Standard (DIN 228) also specifies the quality requirements for wine bottles, including the weight of the bottle. Specifically, for a 750 ml wine bottle, the minimum weight should be 300 grams, and the maximum weight should be 700 grams. For wine bottles of other capacities, the minimum and maximum weights should be appropriately adjusted according to the size of the capacity.

In addition, the Wine Bottle Standard (DIN 228) also specifies the glass thickness of wine bottles to ensure the strength of the bottle. Specifically, for wine bottles of different capacities, the minimum and maximum thicknesses are specified.

In summary, the Wine Bottle Standard (DIN 228) has specific provisions for the weight and glass thickness of wine bottles to ensure their quality and safety. The standard is a German standard and can be viewed and obtained on the official website of the German Institute for Standardization (DIN). The specific steps are as follows:

- Open the official website of the German Institute for Standardization (DIN), the website address is https://www.din.de.

- Enter “DIN 228” in the search box on the homepage and click the search button.

- On the search results page, find “Flaschen für alkoholische Getränke; Flaschen für Wein und Schaumwein; Flaschenformen und -größen” (the German name of the wine bottle standard) and click on it.

- After entering the detailed page of the standard, you can obtain the full content of the standard through paid download, online viewing, or subscription.

The official website of the German Institute for Standardization (DIN) is mainly in German, so a certain level of German reading ability is required. At the same time, the standard acquisition on the website generally requires payment, and the specific fees and methods can be inquired on the website.

Compared with the authoritative national standards, the German standard (DIN 228) is relatively comprehensive and authoritative. Therefore, some of our exported products have undergone LFGB testing, including glass bottles, bottle caps, bamboo caps, and rubber seals. Our factory has also passed the testing and certification of multiple third-party authoritative testing institutions such as SGS, TUV, and Intertek to ensure that our products meet the relevant quality and safety standards.

Post time: 6月-09-2023